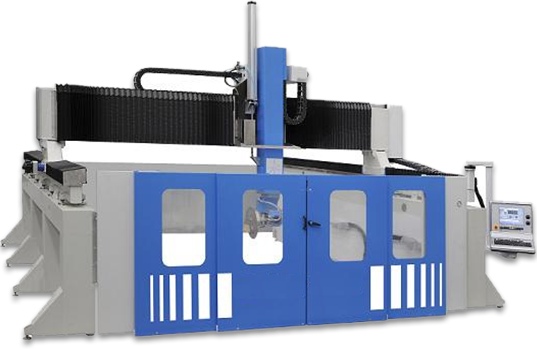

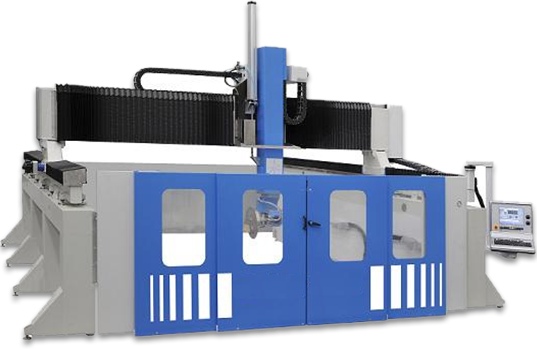

In response to industry demand and our customer’s needs, Rayotek has created a separate grinding facility dedicated to massive grinding operations. Our 5-Axis Grinding System was built after a 3-year engineering project to design the ultimate system for precision grinding and polishing large workpieces. Rayotek’s customized 5-Axis Grinder produces diamond-ground glass, borosilicate, fused quartz, alumina and glass-ceramic materials to virtually any shape. In response to industry demand and our customer’s needs, Rayotek has created a separate grinding facility dedicated to massive grinding operations. Our 5-Axis Grinding System was built after a 3-year engineering project to design the ultimate system for precision grinding and polishing large workpieces. Rayotek’s customized 5-Axis Grinder produces diamond-ground glass, borosilicate, fused quartz, alumina and glass-ceramic materials to virtually any shape.

Rayotek’s massive 5-Axis Grinder turns dreams into reality. Rapid production times along with high precision completely eliminates the need for slower, more traditional grinding methods. In addition, Rayotek’s massive 5-Axis Grinding System can generate shapes and sizes not achievable with other systems.

Typical materials that can be easily ground and polished on our

massive Grinding System:

- Alumina, zirconia, silicon carbide & other refractory materials

- Heraeus TSC series fused quartz & Spectrosil® 2000 fused silica

- Schott Zerodur® glass-ceramic & BK7 optical glass

- Astrosital® glass-ceramic

- Ohara Clearceram® (CCZ) glass-ceramic & BSL7 optical glass

- Corning 7980 fused silica & 7972 ULE® glass-ceramic

- Momentive 124 and 144 fused quartz

Applications that benefit from Rayotek’s Massive 5-Axis Grinding solution:

- Large Optics Blanks – for fast, low-cost large optics, molded and/or precision ground to near net shapes

for master opticians

- Finish Grinding on Cast & Pressed Blanks - for precision, finish grinding on cast large blanks made of of alumina, silicon carbide & other ceramics & refractories

- Massive Optics & Mirrors – for massive astronomy telescopes

- Large Diameter Domes & Spheres – for deep sea submersible, ROVER & lighting

- Large-size Ceramic & Fused Quartz Dies - for metal forming & superplastic metal forming

- Ceramic Nozzles – rocket & missile applications

- Large Thermally Stable Lithography Bases - low expansion materials precision ground to support

lithography systems

- Inspection & QA Tables & Bases – Massive, thermally & mechanically stable inspection tables, tooling & fixturing

- Large scale models – for large-scale size models made from stone, glass, ceramic & stone

What makes our Massive 5-Axis Grinding System capable of achieving so much more than any other service available:

• Unprecedented accuracy for such a large working envelope:

| 5-Axis Grinding System Work Envelope |

| Maximum Grinding X-axis |

163in |

4150mm |

| Maximum Grinding Y-axis |

197in |

5000mm |

| Maximum Grinding Z-axis |

55in |

1400mm |

| Maximum Outside Diameter |

159in |

4030mm |

- Onsite laser mapping of the entire machine for higher accuracy

- In-situ touch probe for establishing and adjusting toolpath.

- Delcam Software System to generate highly accurate G-code for even the most complex curved, facet free surfaces

- An in-house master 5-Axis grinding engineer

- An in-house, world class master optician

- 21 years of experience with diamond grinding complex, optical surfaces

CLICK HERE for more information on Rayotek's large workpiece manufacturing capabilities.

|

|

In response to industry demand and our customer’s needs, Rayotek has created a separate grinding facility dedicated to massive grinding operations. Our 5-Axis Grinding System was built after a 3-year engineering project to design the ultimate system for precision grinding and polishing large workpieces. Rayotek’s customized 5-Axis Grinder produces diamond-ground glass, borosilicate, fused quartz, alumina and glass-ceramic materials to virtually any shape.

In response to industry demand and our customer’s needs, Rayotek has created a separate grinding facility dedicated to massive grinding operations. Our 5-Axis Grinding System was built after a 3-year engineering project to design the ultimate system for precision grinding and polishing large workpieces. Rayotek’s customized 5-Axis Grinder produces diamond-ground glass, borosilicate, fused quartz, alumina and glass-ceramic materials to virtually any shape.