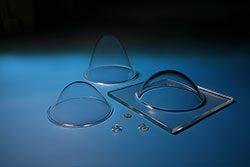

MOLDED OPTICAL CAMERA/VIDEO GLASS DOMES (LOW & HIGH PRESSURE)

WHAT IS A RAYOTEK PTZ CAMERA OPTICAL GLASS DOME?

The ideal molded optical camera dome is not just transparent; it is optically invisible (it cannot be detected in any way by eye or camera). In optical jargon, one would say the "wavefront error" approaches zero. To reduce costs, commercially available molded optical domes are often poorly designed and/or made from plastic or low quality glass, all of which can compromise the image quality transmitting through its walls. Even high quality, more costly glass domes can exhibit compromised signal transmission if not designed properly. Rayotek molded domes are made from high quality, optically clear borosilicate glass using a proprietary non-contact molding process to eliminate mold marks.

COMMON OPTICAL ISSUES WITH MOLDED CAMERA GLASS DOMES:

- Overall Distortion - caused by poor glass dome design, variations in the wall thickness and inhomogeneity of the material. For PTZ camera systems distortion become even more problematic

- Localized Distortion & Speckle - caused by mold marks, bubbles, pits, scratches & other local defects

- Haziness - caused by micro-surface abrasion, devitrification & low quality bulk material

- Reduced Transmission - due to bulk material signal attenuation, exaggerated by poor quality material

- Color Shift & Chromatic Aberration - caused by non-neutral material color filtering & color dispersion

- Parallax Error – due to overall system design including camera positioning

- Fresnel Reflections (aka, Fresnel losses) – a natural surface effect that reduces transmission and causes multiple images & signal loss but can be reduced and/or eliminated by good system design and AR coatings

|

Commercial PTZ Glass Optical Camera Dome |

Custom Glass Optical Camera Domes |

|

In more simple language, the dome material can distort and change the color of an image or light transmitting through it. The better quality the camera dome and dome material, the less it impacts the image or light transmitting through it. Rayotek engineering can work with you to determine the best solutions for your dome requirements.

IMPORTANT LONG-TERM RELIABILITY ISSUES TO CONSIDER IN DESIGNING A MOLDED OPTICAL GLASS DOME:

- Radiation (light) Degradation - exposure to sunlight and intense lighting can cause yellowing and solarization over time, reducing the clarity and color neutrality of dome materials. Not only can many plastics yellow, some cheaper glasses will darken over time with intense lighting, especially when UV is present.

- Thermal Failure & Degradation – plastic domes will embrittle, and loose strength and optical clarity over time when exposed to excessive heat. Glass domes can crack and sometimes even explode when subjected to thermal shock if the wrong glass material is chosen. Not only are the obvious environments such as furnace systems, welding stations, and laser systems a risk, seemingly ordinary environments like a tarmac in the desert or an aircraft carrier deck can get extremely hot and water from a cold hose can cause some glasses to fail.

- Mechanical Stresses - impacts, explosions, abrasion and other environmental hazards can compromise both the optical and mechanical performance of a camera dome. Some glass materials are stronger than others, such as Rayotek borosilicate glass and additionally some glass materials can be strengthened (see below). For more information about glass in high strength applications, see our pages on Aerospace Glass Domes and Marine, Deep Sea & Down-Hole Domes.

Extended Height Deep Sea Optical Camera Dome |

Some solutions to the above quality and reliability issues are simple and relatively low cost to resolve, others are not so simple and thus more costly. It is important that the designer understands both the minimum requirements for the application, as well as the limitations of the imaging and image processing equipment. For example, there is no reason to purchase a high-end camera dome for a low cost camera system used for backing up a vehicle or monitoring fluid levels. On the other hand, a camera dome for a UAV or drone used for high-resolution surveillance may require all items above to be carefully considered and optimized.

|

Questions about what you’ve read so far? Feel free to call and talk with one of our engineers. With over 25 years of experience in glass optics, Rayotek can guide you towards the optimal, cost-effective glass dome design.

HOW TO CHOOSE THE BEST PTZ GLASS DOME FOR YOUR APPLICATION

Rayotek engineering suggests using these key points:

- Get a good understanding of the application requirements to avoid overkill; overkill is normally synonymous with "overcost".

- Determine what the performance limitations are for the actual imaging system. It’s wise to make sure the dome will not interfere with the imaging system’s performance, but beyond that , once again, overkill = overcost.

Integrated Structural Flange on Deep Sea Optical Camera Dome |

- The method of manufacturing can have a big impact on the optical and mechanical performance of the dome and cost of manufacturing.

- Ground and polished domes are traditionally more precise in shape, take much longer to make, and are much more costly.

- Molded glass domes can be press molded or slumped from a flat sheet of glass (float glass).

- Press molded domes tend to have a lot of mold marks and distortion, which is fine for non-optical applications such as lighting.

- Slump molded glass domes, specifically when made from the non-contact Rayotek molding process, actually have a better surface quality than the best ground and polished domes and are significantly lower in cost. The slight reduction in precision of slump molded optical glass domes is, in most cases, still far more than adequate for commercial, and many high tech optical, dome applications.

- The material chosen has a big impact on the optical performance and durability of a glass dome.

- Plastic is the lowest cost material for making optical domes, but over time will degrade and scratch, especially when exposed to heat, wear, intense light, or simple cleaning.

- Slump molded glass domes are typically made from the same types of quality glass as ground and polished domes. A big advantage of the slumping process is slump molded glass domes can be made from readily available, relatively low cost "float" type glass such as soda lime, borosilicate or "Gorilla®" type sheet glasses.

- Rayotek uses hand picked float type glasses with pristine surfaces that require no pre-grind and polish of the starting sheets. In cases where zero-color glasses such as BK7 or more exotic filter glasses are required, sheets can be ground and polished and then slumped. It is harder to control the final wall thickness of slumped glass domes, but in most cases the wall thickness does not compromise the optical performance of an optical glass dome.

Scratch & Impact Resistant Glass Security Camera dome |

HOW TO STRENGTHEN GLASS:

Often, optical domes are exposed to mechanically challenging conditions where it is beneficial to strengthen the glass. There are some glass materials that lend themselves well to strengthening.

Traditional thermal tempering methods ("toughened glass") can be used but will introduce some distortion into the dome because the dome must be heated to close to the softening point, causing the dome walls to warp and distort.

The ideal method for optical dome strengthening is known as chemical strengthening. Chemical strengthening can only be performed on soda lime glass, or, better yet, glasses designed specifically for chemical strengthening, such as Gorilla® Glass by Corning, Dragontrail® glass by AGC and Xensation® Glass by Schott. These unique glasses have made modern cell phone and notepad screens so durable and scratch resistant.

RAYOTEK DOME CAPABILITIES LINKS

If you have a product or system that relies on high quality optical glass domes, for both low and high strength applications, contact us. We have Rayotek engineers that can review your requirements and work with you to find the ideal solution.

Lets talk!

|